Fire Safe Ball Valve Design

What is a "fire-safe" design ball valve?

Fire-safe ball valves are designed to minimize fugitive emissions and downstream leakage in the event of being exposed to high temperatures characteristic of fires. Since most ball valves contain non-alloy components for sealing, it is their ability to maintain functionality at an elevated temperature or at least fail in a predictable way that sets fire-safe ball valves apart from other industrial ball valves.

What are the fire safe standards for valves?

API 607 and API 6FA are the most common design and testing standards for fire-safe ball valves.

API 607: Fire Test for Quarter-turn Valves and Valves Equipped with Nonmetallic Seats

This standard specifies the fire testing requirements and method for confirming the pressure-containing capability of quarter-turn valves with nonmetallic or metallic seat(s) and other operated valves with nonmetallic seating under pressure during and after the fire test. It does not cover the testing requirements for valve actuators other than manually operated gear boxes or similar mechanisms when these form part of the normal valve assembly.

API 6FA: Standard for Fire Test of Valves

This standard establishes the requirements for testing and evaluating the pressure-containing performance of API 6A and API 6D valves when exposed to fire. The performance requirements of this standard establish qualification criteria for all sizes and pressure ratings.

How does a fire-safe ball valve work?

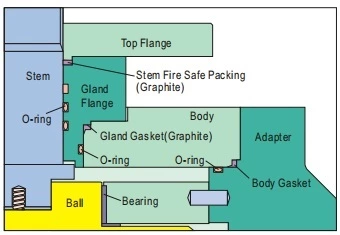

Fire-safe ball valves use fire-proof seals and secondary metal-to-metal seating to provide tight shut-off and prevent external stem leakage.

Fire safe floating ball valve seat design

The method of using a fire-proof seal uses metallic seats, graphite seat inserts, and graphite packings on the stem. In a fire-safe ball valve with a stem packing and seat insert, the graphite remains even when the valve is exposed to fire.

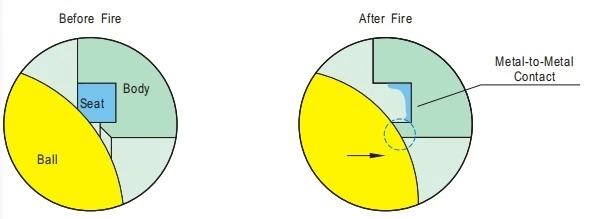

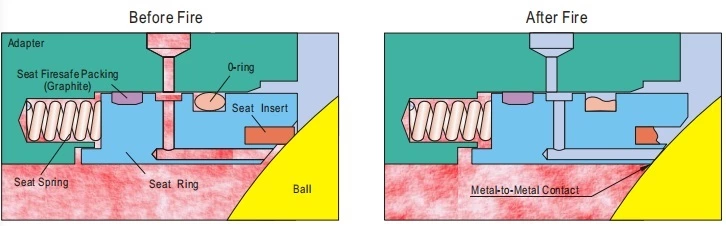

Fire safe trunnion mounted ball valve seat design (secondary metal to metal)

Trunnion mounted ball valve fire-proof seal design

If the seat inserts are destroyed at high temperatures, a secondary metal to metal seat seal is formed between seat and ball.

Fire Safe Certified Ball Valve

All Relia ball valves are fire safe design according to API 607 and API 6FA, and they are tested and certified by TUV.