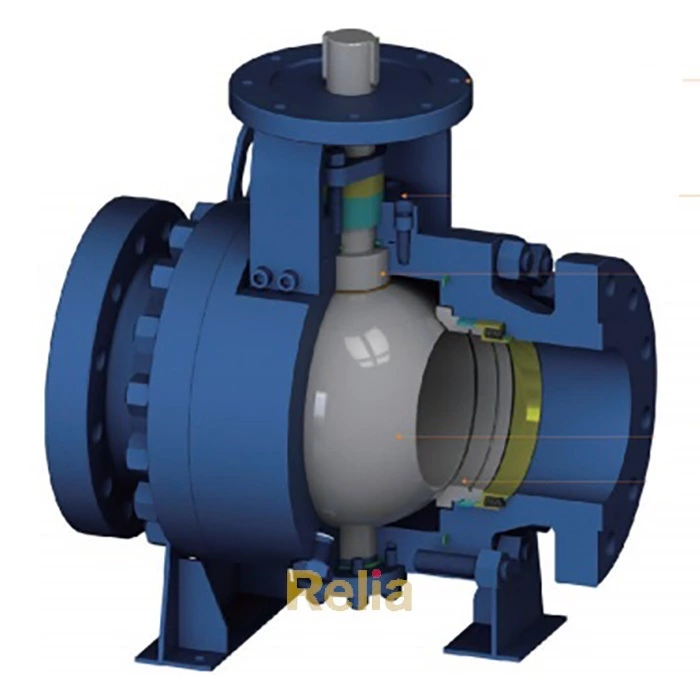

Metal Seated Ball Valve

Metal-seated ball valves are resistant to abrasion, erosion, corrosion, solids, and high temperatures up to 640℃. Special metal-seated ball valves are available in high pressure, big size, top entry, etc. Relia’s scraper seat is ideal for most difficult applications where build-up of damaging fluid deposit may occur on the ball face. Overtime, this occurance to the critical smooth ball surface will cause the ball to become rough and dull rendering the valve inoperative.This problem is most common in pulp making recovery in white, black & green liquors.

Coating Materials

Chrome Carbide (CrC)

Chrome carbide is the standard coating for Relia metal seated ball valves. It has excellent resistance to wear, erosion, and corrosive media and is well suited to extremely high temperature gas or liquid applications.It has some limitations in terms of chlorine services and wet sulfur.

Hard Chromium (HCr)

Hard chromium is suited to a wide range of applications in liquids and gases. It is limited to moderate pressures and temperatures. HCr is not suitable for strong acids or fluids with high chloride contents.

Tungsten Carbide (WC-Co)

Tungsten carbide is very resistant to wear and erosion from slurries, powders, and muds. It works well in cryogenic applications, hydrocarbon gases and

liquids, oxygen, and dry gas services. It is restricted to corrosive services and condensates.

Cobalt-based Alloy

Cobalt-based coatings (Stellite) provide excellent mechanical wear resistance, superior corrosion resistance, and good performance at high temperatures (up to 535 oC). Stellite is used in a lot of applications in pulp and paper industry and in refining applications.

Leave Us Your Info

Could you please kindly fulfill the following information when enquiring:

Valve type (ball, gate, globe, check etc.), valve size, pressure class, valve material, and end connection (flanged, butt welding etc.)