DIB - Double Isolation And Bleed Ball Valve

The DIB ball valve provides double isolation from pressure at both ends of the valve.If a leakage occurs in the upstream seat, the pressure entering the body cavity pushes the downstream seat against the ball and valve seals.

An external body relief valve is installed to protect the body cavity from excess pressure, which can be vented to the atmosphere, recycled back to the upstream side of the valve, or flared.

API defines DIB as a "single valve with two seating surfaces, each of which, in the closed position, provides a seal against pressure from a single source, with a means of venting or bleeding the cavity between the seating surfaces." This feature can be provided in one direction or in both directions.

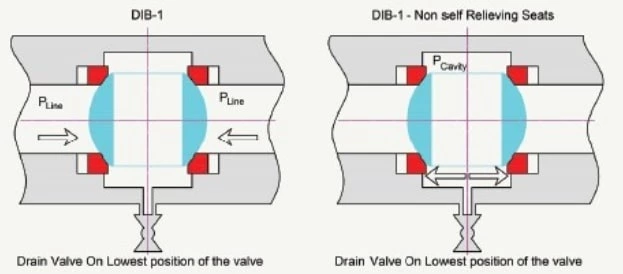

DIB-1 Ball Valve: Double Piston Seat x Double Piston Seat

For the DIB-1 ball valve, with its double piston x double piston configuration, overpressurization of the cavity is external with a safety valve.

Upstream and downstream sealing; pressure activated; and two bidirectional sealing seats.

Advantage: Each seat can isolate the fluid from both upstream and downstream; if one seat is damaged, the other can still perform the sealing function.

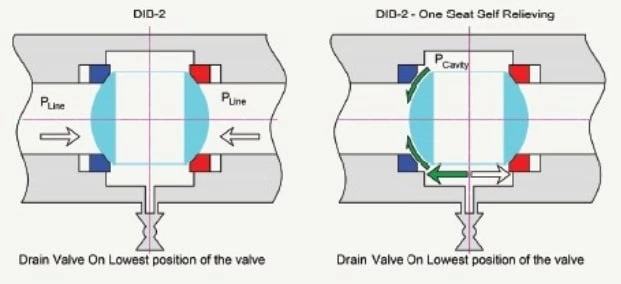

DIB-2 Ball Valve: Double Piston Seat x Self-Relieving Seat

For the DIB-2 ball valve, with its double piston seat x self-relieving seat configuration, cavity overpressurization is internally controlled within the line.

Upstream and downstream sealing; pressure energized; one seat is a bidirectional seat, and one seat is a unidirectional sealing seat.

For the DIB-2 ball valve, the fluid can be relieved from one seat to the downstream side.

Advantage: self-relieving seat; no need to assemble the safety valve for pressure relief.

Both DIB-1 and DIB-2 are for trunnion-mounted ball valve structures.

Applications:

It is important to use a DIB valve in applications that require an additional pressure barrier that seals separately from the main pressure barrier. This is important to fulfill certain operational safety requirements or according to the nature of the service, such as a low tolerance for leakage or the cleanliness of the fluid.