Anti-blowout Stem Ball Valve

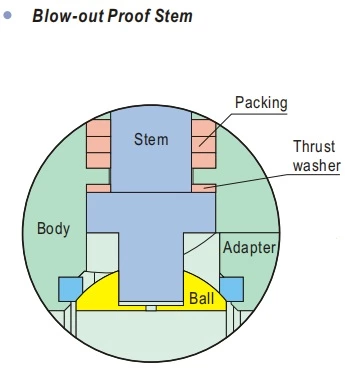

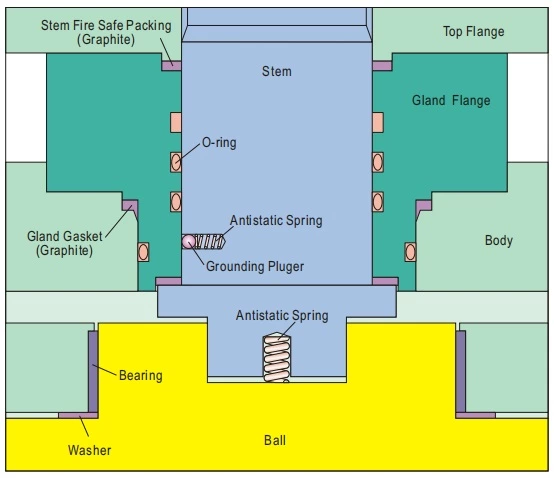

Anti-blowout stem in a ball valve is a safety feature to ensure that the stem is not pushed out of the valve's body by the inline pressure. The anti-blowout stem feature is achieved by integrating an inverted T-shaped shoulder design for the stem that is then inserted from inside the valve's body.

Blow-out Proof Stem In Floating Ball Valve

The stem is sealed by o-rings and packing rings and held in position by the stem housing, which is bolted to the valve body. The o-rings and packing rings are compressed and held in position by the gland flange, which is bolted to the stem housing. Therefore, when we remove the gland flange to replace the graphite packing rings, the stem will still be held securely by the stem housing even when the valve is under pressure.

Anti-Blow-out Stem In Trunnion Ball Valve

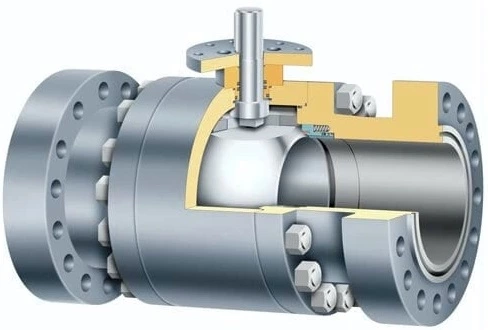

All our ball valves are Anti-Blow-out Stem design as specified in API 6D and BS 5351.

Anti-Blow-out Stem Design Ball Valve