Low-Emission Ball Valves

With more and more concern for environmental protection around the world, low-emission valves will be widely used. Low-emission valves can prevent poisonous, flammable, or explosive media from leaking and polluting the air. It is also critical that low-emission valves reduce fugitive VOC emissions to help soothe the environment.

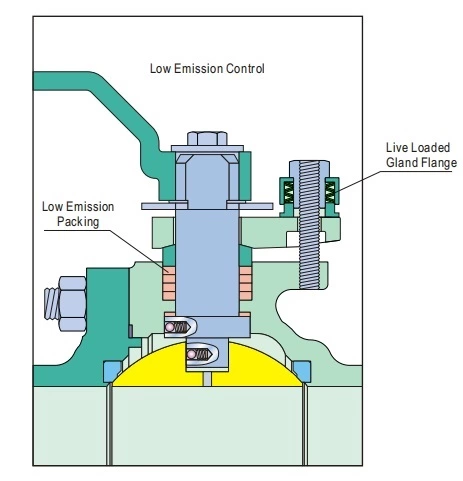

Low-Emission Packing

Relia's low-emission valves use special low-emission packing to ensure the seal of the stem. The cone packing is made of expanding graphite in die-formed rings and has features of high heat resistance, stress relaxation, and low creep.

This unique structure enables a low-friction non-rotary and rising stem valve, providing stabilized sealing performance for long valve life.

The standard V-shaped PTFE packing rings are used in low-temperature service to control emissions.

Environment-Friendly Valve

Accurate machining of stem, gland, and bonnet sealing surfaces with double sealing (O-ring primary seal together with graphite gasket seal) ensure the low emission, which is in compliance with the most severe pollution-control regulations. The test certifications are available on request.

Fugitive Emission Tests

Fugitive emission tests for valves are used to test and evaluate the integrity of the external leakage of valve stem seals (or shafts) and body joints of isolating valves and control valves intended for the application of volatile air pollutants and hazardous fluids.

A qualification test performed with helium, for example, may not provide results that are relatable to verification methods used in the field, such as EPA Method 21. This is not to say that qualifications performed with helium would not be acceptable; it is, however, advisable to ensure that it is acceptable to all parties.

Fugitive Emission Standards

Brief comparison of Fugitive Emissions standards ISO and API

| ISO 15848-1 | ISO 15848-2 | API 622 | API 641 | |

| Qualifies | Valve types | Production valves where fugitive emission standards are specified | Packing suitable from 20° F to 1000° F ( 29 to 538° C) | Valve design up to NPS 24 and 1500 Class |

| Pre-Requisite | None | ISO 15848-1 qualified valve design | None | API 622 qualified packing |

| Test Medium | Helium or methane | Helium | Methane | Methane |

| Packing Tested In | Valve | Valve | Fixture | Valve |

| Test Pressure | Rated valve pressure at test temperature per ASME B16.34 | 87 psi (6 bar) | 0–600 psi (0–41.4 bar) |

The lower of 600 psi (41.4 bar) or maximum allowable pressure at temperature per ASME B16.34 |

| Test Temperature | Variable up to 752° F (400° C)1 | Ambient | Ambient and 500° F (260° C)2 | Ambient and 500°F(260℃)2 |

| Mechanical Cycles | Variable1 | 5 | 1510 | 610 |

| Thermal Cycles | Variable 1 | 0 | 5 | 3 |

| Allowable Packing Adjustments | 1 | 0 | 0 | 0 |

| Measured Units | mg/sec-m | ppm | ppm | ppm |

| Acceptance Criteria | Variable1 | Variable3 | 500 ppm | 100 ppm |

| Qualification Coverage | Same basic design. Stem diameters: 50% lower and 200% higher. Pressure class: same class and lower5 | N/A | Packing Only | Variable4,5 |

Note:

1- ISO 15848-1 has several different classification criteria for classes for the allowable leakage rates, number of mechanical test cycles and test temperatures.

2- There is a proposal for higher temperature testing.

3- Acceptance criteria are based on the tightness class the design was tested to per ISO 15848-1.

4- Valve must be the same basic stem and packing design.

5- The scope of the standard is 150 to 1500 Class and valves NPS 24 and smaller.

Reference Standard

API Standard 622: Fugitive emissions testing of process valve packing in a test fixture subject to pressure, temperature, and mechanical cycles.

API Standard 624: Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions.

API Standard 641: Type Testing of Quarter-Turn Valves for Fugitive Emissions. Ball, butterfly, and plug valves with API Standard 622-compliant packing if graphite is used or various elastomer options at a range of temperatures.

ISO 15848-1: Industrial Valves—Measurement, Test, and Qualification Procedures for Fugitive Emission.